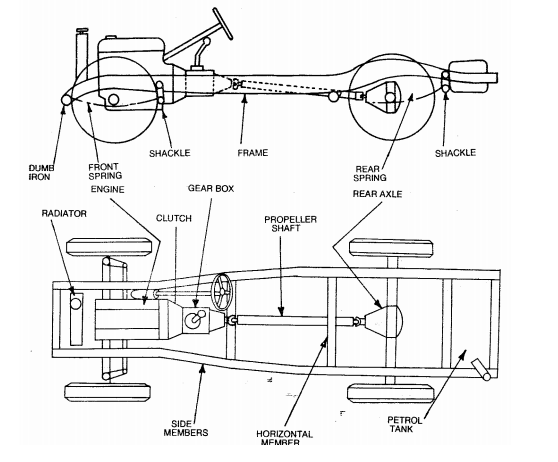

CHASSIS FRAME AND BODY

Introduction of Chassis Frame: Chassis is a French term and was initially used

to denote the frame parts or Basic Structure of the vehicle. It is the back bone

of the vehicle. A vehicle with out body is called Chassis. The components of

the vehicle like Power plant, Transmission System, Axles, Wheels and Tyres,

Suspension, Controlling Systems like Braking, Steering etc., and also electrical

system parts are mounted on the Chassis frame. It is the main mounting for all

the components including the body. So it is also called as Carrying Unit.

Layout of Chassis and its main Components:

The following main components of the Chassis are

1. Frame: it is made up of long two members called side members

riveted together with the help of number of cross members.

2. Engine or Power plant: It provides the source of power

3. Clutch: It connects and disconnects the power from the engine fly

wheel to the transmission system.

4. Gear Box

5. U Joint

6. Propeller Shaft

7. Differential

FUNCTIONS OF THE CHASSIS FRAME:

1. To carry load of the passengers or goods carried in the body.

2. To support the load of the body, engine, gear box etc.,

3. To withstand the forces caused due to the sudden braking or

acceleration

4. To withstand the stresses caused due to the bad road condition.

5. To withstand centrifugal force while cornering

TYPES OF CHASSIS FRAMES:

There are three types of frames

1. Conventional frame

2. Integral frame

3. Semi-integral frame

1. Conventional frame: It has two long side members and 5 to 6 cross

members joined together with the help of rivets and bolts. The frame sections

are used generally.

a. Channel Section - Good resistance to bending

b. Tabular Section - Good resistance to Torsion

c. Box Section - Good resistance to both bending and

Torsion

2. Integral Frame: This frame is used now a days in most of the cars. There is

no frame and all the assembly units are attached to the body. All the

functions of the frame carried out by the body itself. Due to elimination of

long frame it is cheaper and due to less weight most economical also. Only

disadvantage is repairing is difficult.

3. Semi - Integral Frame: In some vehicles half frame is fixed in the front end

on which engine gear box and front suspension is mounted. It has the

advantage when the vehicle is met with accident the front frame can be

taken easily to replace the damaged chassis frame.

This type of frame is used in FIAT cars and some of the European and American cars.

VARIOUS LOADS ACTING ON THE FRAME:

Various loads acting on the frame are

1. Short duration Load - While crossing a broken patch.

2. Momentary duration Load - While taking a curve.

3. Impact Loads - Due to the collision of the vehicle.

4. Inertia Load - While applying brakes.

5. Static Loads - Loads due to chassis parts.

6. Over Loads - Beyond Design capacity.

THE DIFFERENT BODIES USED IN AUTOMOBILES:

The Automobile bodies are divided in two groups

According to Chassis design the body can divided into

1. Conventional Type

2. Integral Type

3. Semi- Integral Type

According to other usage:

1. Light vehicle Bodies - cars, jeeps

2. Heavy vehicle Bodies – Busses, Lorries

3. Medium vehicle Bodies - Vans, Metadoors

REQUIREMENTS OF BODIES FOR VARIOUS TYPES OF VECHILE:

The body of the most vehicle should fulfill the following requirements:

1. The body should be light.

2. It should have minimum number of components.

3. It should provide sufficient space for passengers and luggage.

4. It should withstand vibrations while in motion.

5. It should offer minimum resistance to air.

6. It should be cheap and easy in manufacturing.

7. It should be attractive in shape and colour.

8. It should have uniformly distributed load.

9. It should have long fatigue life

10.It should provide good vision and ventilation.

STEERING SYSTEM

Introduction: This system provides the directional change in the movement of

an Automobile and maintain in a position as per the driver’s decision without

much strain on him.

REQUIREMENTS OF STEERING SYSTEM:

a. It must keep the wheel at all times in to rolling motion with out

rubbing on the road.

b. This system should associate to control the speed.

c. It must light and stable.

d. It should also absorb the road shocks.

e. It must easily be operated with less maintenance.

f. It should have self-centering action to some extent.

Functions of Steering System:

1. It helps in swinging the wheels to the left or right.

2. It helps in turning the vehicle at the will of the driver.

3. It provides directional stability.

4. It is used to minimize the tyre wear and tear.

5. It helps in achieving self-centering efforts.

6. It absorbs major part of the road shocks.

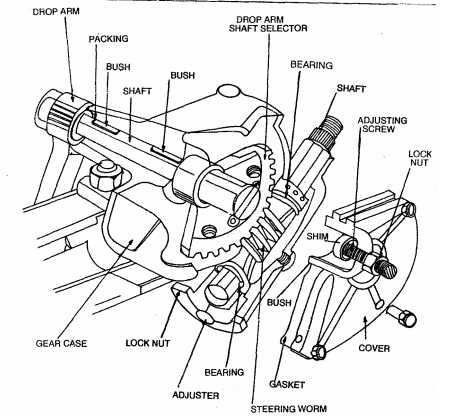

Main Components of Steering System:

The following are the main components of steering system are

1. Steering Wheel

2. Steering column or shaft

3. Steering Gear

4. Drop Arm or Pitman Arm

5. Drag Link

6. Steering Arm

7. Track-Arms

8. Track Rod or Tie-Rod

9. Adjusting Screws

Types of Steering Gear Boxes:

1. Worm and Wheel Steering Gear.

2. Worm and Roller Steering Gear.

3. Re-circulating Ball type Steering Gear.

4. Rack and Pinion type Steering Gear.

5. Cam and Roller Gear type Steering Gear.

6. Cam and Peg Steering Gear.

7. Cam and Double lever Steering Gear.

8. Worm and Sector Type Steering Gear.

Functions of Steering Gear Box:

1. It converts the Rotary movement of the steering wheel in to the

angular turning of the front wheels.

2. It also multiplies drivers efforts and give MEHANICAL ADVANTAGE.

1.Worm and Wheel Type: This type of steering gear has a square cut screw

threads at the end of the steering column; which forms a worm, at the end of

it a worm wheel is fitted and works rigidly with it. Generally covered shaft is

used for the worm wheel. The worm wheel can be turned to a new position

the drop arm can be readjusted to the correct working position.

2. Re-circulating Ball Type: In this type of gear box the endless chain of balls

are provided between the worm and nut members. The nut form a ring of

rack having an axial movement.

So that the sector on the rocker shaft racks,

the balls roll continuously between the worm and nut. Being provided with

return chambers at the ends of the worm. This method reduces friction

between worm and nut members. This type of steering gear is used for heavy

vehicles.

3. Rack and Pinion Type: This is common manual type of steering gear box

is used in most of the vehicles. In this type of steering a pinion is provided the

bottom end of the steering column. The teeth of the pinion wheel in mesh

with corresponding teeth provided on the rack, the end of which are

connected to the stub axle through the rod. The rotating motion of the

pinion operates the rack in FORE and AFT direction which in turn operates the

stub axle.

4. Cam and Lever Type: The cam and lever steering uses one or two lever

studs fitted in taper roller bearing. When the worm in the form of helical

groove rotates the stub axle and it also rotates along with it. This imports a

turning motion to the drop arm shaft.

5. Worm and Sector Type: In this type the worm on the end of the steering

shaft meshes with a sector mounted on a sector shaft. When the worm is

rotated by rotation of the steering wheel, the sector also turn rotating the

sector shaft. Its motion is transmitted to the wheel through the linkage. The

sector shaft is attached to the drop arm or pitmen arm.

Power Steering: Power steering reduces much strain on the part of the driver

while negotiating sharp curves. It makes easy to turn sharp corners. It is usually arranged to be operative when the effort of steering wheel exceeds a predetermined value. It is fitted on heavy commercial vehicles and medium

cars.

Steering Linkages: Steering Linkage is a connection of various links between

the steering gear box and the front wheels. The motion of the pitman arm

and steering gear box is transferred so the steering knuckles of the front

wheels through the steering linkages. The swinging movement of the pitman

arm from one side to the other side gives angular movement to the front

wheel through the steering linkages.

Types of steering Linkages:

1. Conventional steering Linkage.

2. Direct cross type steering linkage

3. Three piece steering linkage

4. center arm steering linkage

5. Relay type steering linkage.

Slip Angle: The angle between direction of the motion of the vehicle and the

center plane of the tyre is known as Slip Angle. It ranges from 8º to 10º.

Under steer: When the front slip angle is greater than that of rear, the vehicle

tends to steer in the direction of side force. Then it is known as under steer. This

provides greater driving stability, especially when there is a side wind.

Over Steer: When the rear slip angle is greater than that of front slip angle,

the vehicle tends to mover away from the direction of center path. This is

known as over stear. This is advantageous when the vehicle moving on the road having many bends curves.

Steering Gear Ratio or Reduction Ratio: It has been defined as the “ number

of turns on the steering wheel required to produce on turn of steering gear

cross shaft to which the pitman arm is attached. Generally it varies between

14'.1 and 24'.1.

Turning Radius: It is the radius of the circle on which the outside front wheels

moves when the front wheels are turned to their extreme outer position. This

radius is 5 to 7.5 m for buses and trucks.Wheel Alignment: It returns to the positioning of the front wheels and steering

mechanism that gives the vehicle directional stability, reduce the tyre wear

to a minimum.

Factors effects the wheel alignment:

1. Factors pertaining to wheel:- a. Balance of wheels(Static and Dynamic)

b. Inflation of tyre.

c. Brake adjustments.

2. Steering Linkages.

3. Suspension System

4. Steering Geometry –a. caster b. camber c. king pin inclination d. toe-in

and toe-out etc.,

Steering Geometry: It refers to the angular relationship between the front

wheels and parts attached to it and car frame.

The steering Geometry includes

1. Caster angle

2. Camber angle

3. King-pin inclination

4. toe-in

5. toe-out etc.,

Caster Angle: This is the angle between backward or forward tilting of the

king pin from the vertical axis at the top. This is about 2º to 4º. The backward

tilt is called as positive caster. The forward tilt is called negative caster.

Camber: The angle between wheel axis to the vertical line at the top is

called camber angle. It is approximately ½º to 2º. King-pin inclination: It is the angle between vertical line to the king pin axis.

The inclination tends to keep wheels straight ahead and make the wheels to

get return to the straight position after completion of a turn. The inclination is

normally kept 7º to 8º.

Toe-in: It is the amount in minimum at the front part of the wheel points

inwards approximately 3 to 5 mm. It prevents side slipping excessive tyre

wear, proper rolling of front wheels and steering stability.

Toe-out: It is the difference in angles between two front wheels and vehicle

frame during turning. It is used to prevent dragging of tyre during turn.

Reversible steering: When the deflection of road wheels is transmitted

through the steering wheel to road surface, the system is called Reversible.

If every imperfection of road surface causes the steering to rotate, it

causes much strain on the part of the driver to control the vehicle. It causes

much strain on the part of the driver to control the vehicle. There fore such of

the reversibility is not desired. But, some degree of reversibility desired, so that

the wheel becomes straight after taking a curve.

Irreversible steering: If the front road wheels does not transfer any deflection

to the steering which is called irreversible steering. After negotiating a curve

and the steering wheel not returned easily, there causes the production of un due stresses on the steering mechanism, therefore some degree of

irreversible also desired.

Steering Mechanism: There are two types of steering gear mechanisms

1. Davis Steering gear 2. Ackermann Steering gear

1. Davis Steering Gear: The Davis Steering gear has sliding pair, it has more

friction than the turning pair, there fore the Davis Steering Gear wear out

earlier and become inaccurate after certain time. This type is mathematically

Accurate.

The Davis gear mechanism consists of cross link KL sliding parallel to

another link AB and is connected to the stub axle of the two front wheel by

levers ACK and DBK pivoted at A and B respectively. The cross link KL slides in

the bearing and cross pins at its ends K and L. The slide blocks are pivoted on

these pins and move with the turning of bell crank levers as the steering

wheel is operated. When the vehicle is running straight the gear is said to be

in its mid-position. The short arms AK and BL are inclined an angle 90 t α to

their stub axles AC and BD respectively. The correct steering depends upon

the suitable selection of cross arm angle α, and is given by

Tan α = b/2l Where b= AB = distance between the pivots of front axle.

l=wheel base

2. Ackermann Steering System: It has only turning pair. It is not

mathematically accurate except in three positions. The track arms are made

inclined so that if the axles are extended they will meet on the longitudinal

axis of the car near rear axle. This system is called ackermann steering.

0 comments:

Post a Comment